Thank you for signing up for our BMS Testing Webinar.

Please enjoy the on-demand video as well as the Q&A below.

Question: Very interesting presentation! Will slides and recording be available?

Answer: Yes. See link here to the presentation.

Q: Can the testing capabilities predict the life of BMS? And, if yes, when AI supported BMS claims extended battery life to 30-40% from the same cell chemistries? Can such claims be tested by simulation?

A: You can use our products to accelerate the testing cycles. For example, you can simulate thousands of charging/discharging cycles in a matter of minutes, which would be impossible if you're using a real battery pack. You can also simulate extreme conditions and see how your BMS reacts to them. This data can be fed into your AI model to predict the life of your BMS.

Q: With new PXI modules being regularly introduced, would a PXI-based system be more prone to obsolescence issues?

A: No, you'll be more protected from obsolescence due to the availability of vendors. Additionally, due to the nature of PXI, it is relatively straightforward to design out obsolescence and update products.

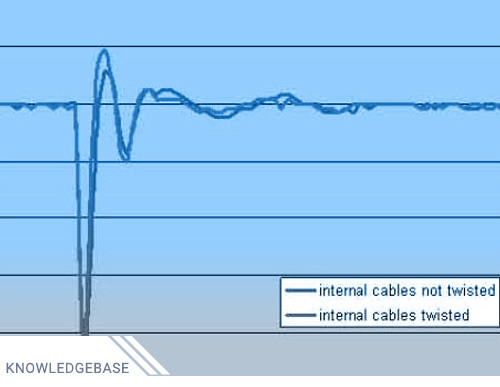

Q: Why not just use a power supply with a series of potential dividers for cell emulation?

A: The main reason to use a simulator instead is that standard power supplies do not respond to load changes as quickly as a simulator. In addition, depending on the application, you may need to adjust the cells to ensure the BMS is reading the channels correctly and trigger and aid in cell balancing.

Q: How is Pickering handling the current move by automotive manufacturers to 800V and higher battery stacks to reduce charge time?

A: We constantly monitor the market and where it's going and develop products to support these needs. For example, we just released a 1000V isolation battery simulator to meet these needs directly.

Q: Can I use Linux to program a PXI-based BMS test system?

A: Yes, you can. We provide a universal Linux driver covering all major Linux operating system flavors.

Q: Can the Test System handle both high-voltage and low-voltage interfaces to the Battery Controller?

A: Yes, the advantage of a PXI system is that you can select the appropriate module for the given application and signals.

Q: What are the more appropriate plant model simulation tools that can be integrated (Such as PLECS, MATLAB/Simulink or Saber, Amesim)?

A: We are providing a means of creating any simulation model with the capability for users to use existing available models. For example, if you have a certain lithium-ion battery charging/discharging simulation model, you can apply this to our hardware to create a digital twin to your battery.

Q: What sort of faults can the Test system support without damaging the Battery controller (BMS) – short to ground, short to power, cross shorting across BMS pins, etc.?

A: This is dependent on your BMS. We are providing the capability to test these scenarios and how your BMS reacts to these conditions. For example, if it's designed to protect against a short, it can be simulated and tested. Otherwise, it could be destructive.

Q: LIN bus communication compatibility?

A: Our solution is based on the PXI standard, and some manufacturers provide PXI cards capable of supporting LIN capability, a major advantage of using an industry-standard like PXI.

Q: Is this product meant for laboratories or direct manufacturers of BMS's?

A: Both; during the rapid prototyping phase, you can use this tester to verify different elements of your BMS design. You can also use this tester for end-of-line testing where repeatability is critical.

Interested in learning more today? Take a look at our other on-demand webinars & videos.

Questions? Start a conversation with us today

DESIGN

The agility and expertise needed so you can develop a system that meets your requirements

Quickly define test system switching utilizing the latest advancements in hardware and software

- 1000+ PXI, PCI, LXI & USB products

- Scalable platforms as your needs evolve

- 3D models help create the documentation to replicate your test systems

DEPLOY

Resources to reduce test integration time and increase test throughput

We'll accelerate the process with tools to help with your programming efforts.

SUSTAIN

Maintain your test system when in production to measure the success of the development effort

Maximize uptime and lower your cost of ownership with quality hardware, diagnostic tools, and access to experienced support

- 3-year warranty on all of our solutions

- Quality products endure for 15+ years

- Top tier technical product support